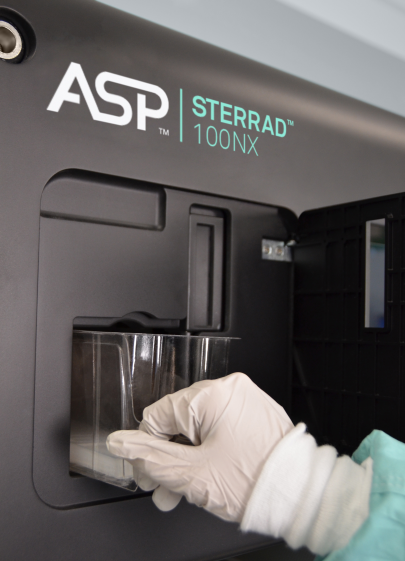

Product Overview

Just Load & Go - Put sterilization in the efficient & capable hands of the STERRAD™ 100NX with ALLClear™ Technology

STERRAD™ Systems continue to be the market leader in hydrogen peroxide based low-temperature sterilization with over 20,000 systems installed globally. Healthcare institutions around the world have trusted STERRAD™ Systems for decades to sterilize medical instruments and materials, eliminating toxic residue. STERRAD™ 100NX System with ALLClear™ Technology is one of the latest releases from the STERRAD™ Systems platform and is the culmination of over 25 years of innovation in hydrogen peroxide gas plasma (HPGP) sterilization technology.

The ALLClear™ Technology within the system increases sterilization productivity by conditioning the load, checking for moisture, and running system diagnostics prior to sterilization cycles to maximize successful cycle runs. The system also has integrated quality systems to enhance compliance to guidelines and hospital policies and is ready to integrate with ASP ACCESS™ Technology and STERRAD VELOCITY™ Reader to automate your reprocessing experience, making your data audit-ready.

Gas plasma is documented to actively break down hydrogen peroxide, reducing emissions exposure for sterile processing staff, leaving only the elements of water and oxygen behind. The proposed mechanism of action of this device is the production of free radicals within a plasma field that are capable of interacting with essential cell components (e.g., enzymes, nucleic acids) and thereby disrupt the metabolism of microorganisms.1

STERRAD™ 100NX System with ALLClear™ Technology currently includes up to four sterilization cycles - STANDARD, EXPRESS, FLEX, and DUO – to sterilize a variety of medical devices, supported by device validations working in close collaboration with medical device manufacturers.

Featuring an upgradeable platform, STERRAD™ 100NX System with ALLClear™ Technology is designed to adapt to the upcoming demands of sterile processing as medical device designs and guidelines evolve over time.

Innovator of Hydrogen-Peroxide-Based Sterilization

- Pioneers in vaporized hydrogen peroxide and hydrogen peroxide gas plasma sterilization technology for over 25 years

- Over 15 million cycles successfully completed worldwide each year, and more than 20,000 medical device manufacturer endorsements (accessible via STERRAD™ Sterility Guide), impacting millions of patients annually

- Comprehensive device validation program working with device manufacturers to test sterilization efficacy, material compatibility, and device functionality

Compliance is Crucial - Enhance Compliance, Automatically2

- Quality control that enhances compliance with hospital policies and device IFUs

- Minimize the need for manual record keeping - automatic communication of information between the STERRAD™ System, ASP ACCESS™ Technology, STERRAD VELOCITY™ System, and an instrument tracking system or hospital network

Designed with Simplicity in Mind

- Simple, easy-to-use system that reduces operator error

- Enhanced user interface makes cycle navigation intuitive and straightforward

- Minimizes start-up delays and confusion

- Enables fast and easy staff training

Designed with Your Priorities in Mind

- Future-focused System: Upgradeable technology that enhances system capability

- Trusted Sterility: Sterility assurance from the leader in low-temperature sterilization

- Safety Considerations: Designed to minimize healthcare worker chemical exposure

- Reduced Costs: Delivers ongoing economic value

Upgradeable, All-in-one System

- Upgradeable platform to adapt to upcoming demands of sterile processing as medical device designs and guidelines evolve over time

- ALLClear™ Technology to assist load issues prior to starting a sterilization cycle, minimizing cycle cancellations

- Integrated quality system within system design to enhance compliance to guidelines and hospital policies3

Software

ASP ACCESS™ Data Station

Automate your experience to reduce potential for human error and provide audit-ready data

- Communicates information automatically between STERRAD™ Systems and STERRAD VELOCITY™ Reader to display errors

- Automates and digitizes the documentation of sterilizer and BI records

- Connects to your hospital Instrument Tracking System to provide audit-ready data

- Receives reprocessing data, trends, and alerts to effortlessly review data

- Browser-based access from any location using the cloud application

- Tablet & smartphone compatible

Consumables

- STERRAD™ 100NX System Cassettes4

- STERRAD VELOCITY™ Biological Indicator (BI)/Process Challenge Device (PCD)

- STERRAD™ Chemical Indicator (CI) Strips

- SEALSURE™ Chemical Indicator (CI) Tape

- Tyvek® Pouches

User's Guide

The ASP IFU and User Guide library allows users to search by language, country and product to locate the appropriate instructions for use of ASP Products. Product literature and availability varies by country. Check out this helpful reference site to locate the STERRAD™ 100NX System with ALLClear™ Technology instructions for use.

View and download User's Guide

References

- Guideline for Disinfection and Sterilization in Healthcare Facilities, 2008, Centers for Disease Control and Prevention

- STERRAD™ Systems with ALLClear™ Technology have features that may enhance compliance, such as on-screen reinforcement of user training.

- Integrated quality control features include items such as on-screen reinforcement of user training

- As a precaution, when handling any part of the system or load items that have been exposed to hydrogen peroxide, please wear the appropriate PPE (chemical-resistant latex, PVC/vinyl or nitrile gloves). Refer to the glove manufacturer's instructions for use for more information.

The third-party trademarks used herein are the properties of their respective owners.