A Look Back: 2019 Case Study Highlights

Explosive Growth And Initial Challenges

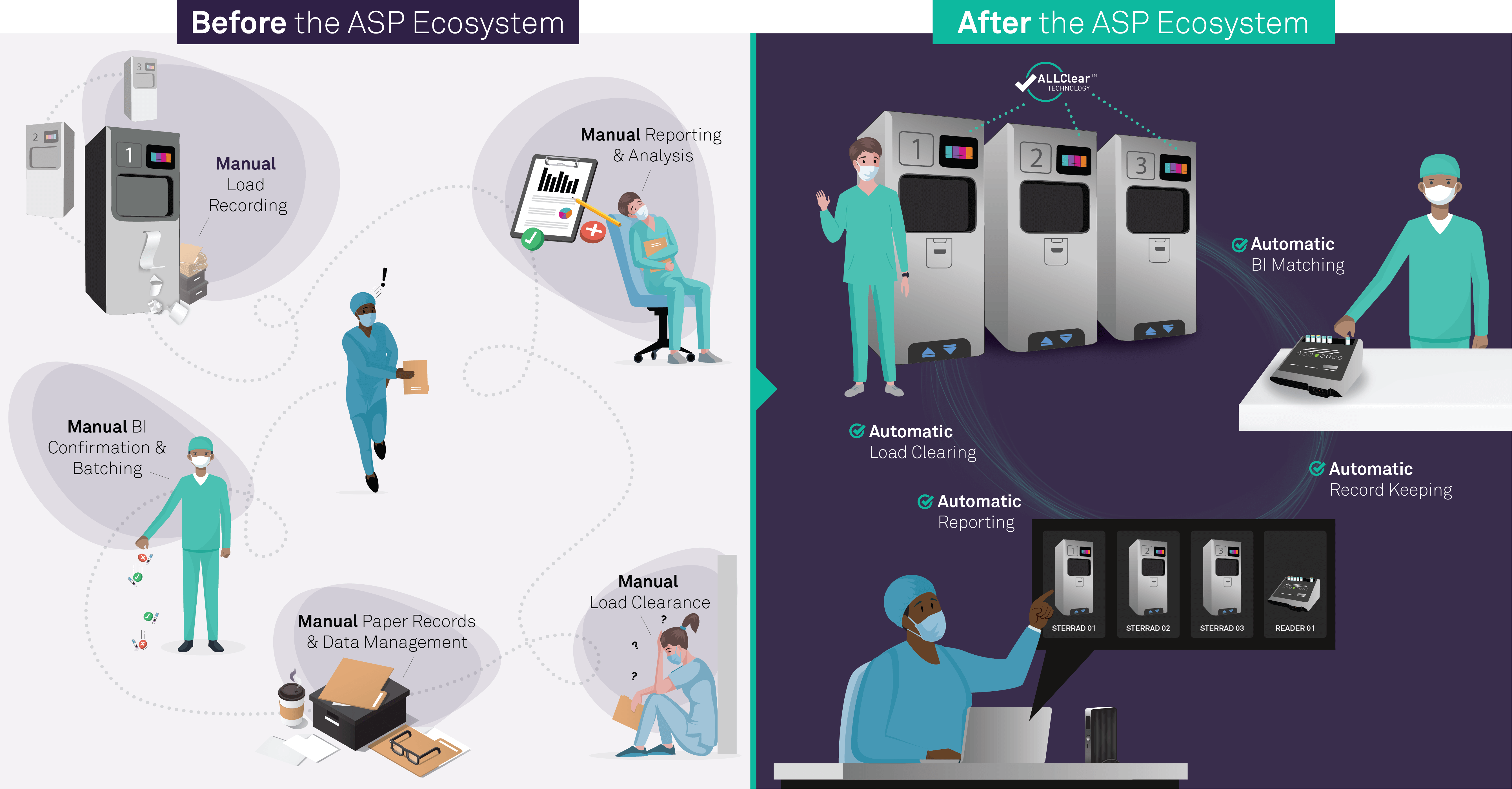

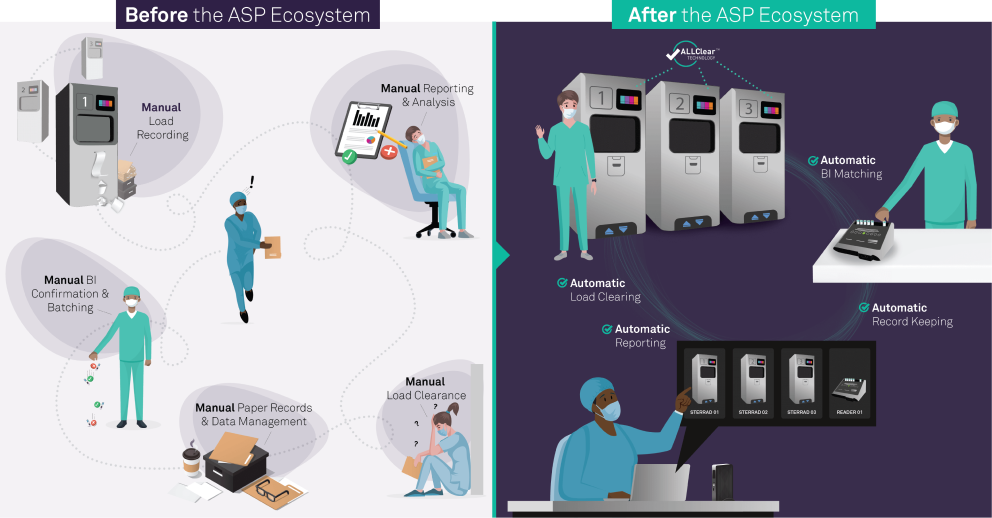

Explosive procedure growth at Sanford Medical Center Bismarck pushed their Perioperative Services Management Team to seek solutions to increase productivity and accuracy in their sterilization processes. By integrating the ASP Ecosystem, Sanford Health eliminated manual record-keeping and standardized their instrument reprocessing, leading to significant improvements in efficiency and error reduction.

A Continued Success Story

Five years after our initial study, we returned to Sanford Medical Center Bismarck to assess the ongoing impact of the ASP Ecosystem. Despite challenges posed by the COVID-19 pandemic and an SPD renovation, Brandi Everding, the SPD Manager, shared valuable insights.

Increased Efficiency

“Sterile Processing is a busy place. Anywhere that we can look to create more efficient processes is an overall benefit for our team.”

The ASP Ecosystem continues to enhance workflow efficiency, freeing staff from manual data entry and allowing them to focus on critical tasks. By automating routine processes, the system streamlines operations and reduces the risk of errors.

Adaptation During SPD Renovation

“Things are constantly changing in healthcare. You simply have to adapt. Technology advancements are one way to help your team thrive in this ever changing environment.”

Brandi Everding emphasized the importance of automation during their planned SPD renovation. Despite operating from a mobile unit, the ASP Ecosystem ensured that sterilization standards were consistently met and workflows remained stable. This adaptability was crucial during the renovation phase.

Reliability During Crisis

“There is so much riding on the work we do in our department. We need systems that function well and provide reliability. It eases the burden and stress.”

Even during the pandemic, the automated systems maintained their reliability, ensuring that the facility’s high standards of care were met despite reduced staff availability. The ASP Ecosystem proved its resilience during challenging times.

Ongoing Improvement

“We have recently started a quality project around tray weights. ASP’s device compatibility website has assisted in providing validated cycles and parameters for compatibility. We are working towards 100% compliance with total load capacity.”

The technology enables continuous process improvements in all areas of the SPD. With each component of the Ecosystem working in harmony, the SPD team can make informed decisions to optimize sterilization procedures. Fewer interruptions and uncertainties lead to increased productivity.

Long-Term Reliability

“We have used STERRAD™ Systems for many years. Recently, we replaced our 100S, which had been in the SPD since 1997. We have had the Ecosystem in place for 5 years. We have mostly upgraded to 100NX sterilizers and really appreciate the functionality of the whole Ecosystem and how it helps our department reduce the risk of human error. This is a no-fail system. We have had minimal issues with downtime or interruptions of service.”

Automation not only reduced errors but also allowed the SPD to handle increased volumes without compromising quality. The system’s reliability over the years has been a cornerstone of efficient daily operations.

Staff Productivity

“Work smarter, not harder! We are always looking for the next best way to create a process improvement. The Ecosystem has been ahead of the game in technology, ease of use and reliability. This system has earned ROCK STAR status in our department.”

With fewer manual tasks, staff can focus on critical thinking and communication. The ASP Ecosystem empowers them to work smarter, contributing to overall productivity gains.